An excerpt from “Some Other Day: Remembering Empire” by the Empire Area Heritage Group

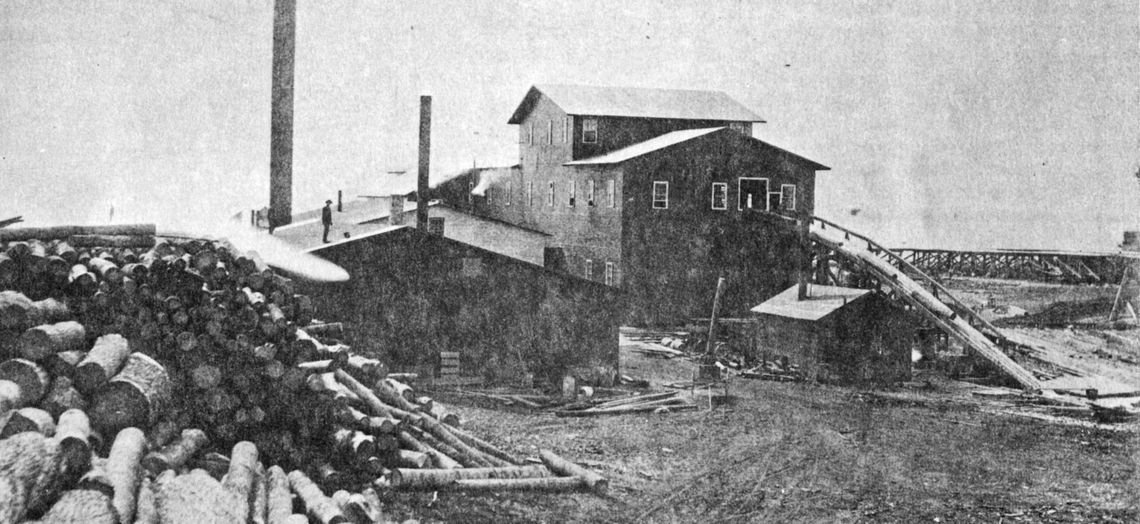

When flat cars came in loaded with logs, they were rolled down the timbers into the water. Here the lake was dredged out deep enough to let any log float, and slabs were built up about two feet above the water. This made good footing when the logs were pulled by a pike-pole to a slide. An endless chain in the slide with two hooks then pulled them up into the mill by steam power, and they were sawed into lumber, slabs and edgings.

Another group of workers started grading the railroad bed where it was staked out east of the bridge. Teams of horses and slip scrapers were used to grade down the knolls and fill in the low places with sand. This continued east for two miles, then turned southeast for two miles, gradually climbing a large hill on the way.

In the meantime, thousands of railroad ties were made, some sawed out by the mill, and some hewed out with axes by workers along the railroad. These varied in size, as some were eight include by eight inches and others six inches deep by eight inches,, 10 inches or 12 inches wide, and they were about eight feet long. These were spaced about 16 inches apart on the railroad, and were buried in the sand, so that about one inch of the top surface was exposed to the air. But each tie had to fit snug against the rail and conform with the slope of the railroad bed.

The rails had to be kept straight, and very close to the same width all the way. And there were special rails that could be pushed back from the main rail, or up against it by a lever. This is called a switch and lets the engine and cars go on another track. All rails used a special spike to dive into the ties. This holds them firm. One bad feature is that the ties decay quite fast in the sand.

The flat cars were now loaded with rails and ties, and with the engine pushing these in front, a small section of the railroad each finished each day.

A name was given to the railroad now, and it was called “The Empire and Southeast Railroad.”

The railroad starting at Empire was fine for the Wilce Company. In a short time, the road was going into virgin timber all the time, and flat cars loaded with logs were brought into the mill six days a week. This could continued in summer or winter, and was a lot difference than hauling logs with horses and sleighs in winter. Very few logs could be hauled in summer.

Problems Storing Lumber But now a problem came up. At first only a couple of trams or runways with lumber piles on each side were built, and I mentioned these earlier. They started at the west end of the mills, and ran north about onehalf the distance to the north dock. Only hardwood lumber such maple or beech was piled here. But each runway with lumber on each side took about 50 feet of space, east and west.

The problem was that the mill was cutting hardwood lumber faster than boats could ship it to Chicago, especially in winter when the ice formed along the shore and along the docks. Thus the boats could not come in to load. Now more space for lumber piles were needed and the only way to go was toward Lake Michigan. The railroad, a wagon road, and other essential things prevented the use of space for other purposes east toward South Bar Lake. Toward the north, most of the land was used for huge piles of slabs and edgings.

When the mill was built, the Lake Michigan shore was probably 150 feet or more from the west end of the mill. But the beach came in some distance from the shore, and this did not leave the space needed.

So now thousands of slabs and edgings were dumped into Lake Michigan from the south dock on north to about towthirds the distance to the north dock. These were piled on top of each tier until they were above the water line. Then more were hauled over the top and dumped into deeper water. This continued until the water on the outside edge was from six to 10 or 12 feet above the water line. On the outside edge the slabs were cross-piled to keep the waves from washing the edges them out, and came straight up from the bottom of the lake. Also a liberal amount of sand and sawdust was spread over the bottom of the lake and made a firm foundation. No filling was necessary on land near the lake as the bank along the shore was about seven feet high.

This was a tremendous project and I still cannot see how they accomplished it. But they used quite a group of laborers and used teams of horses to do all the heavy work.

Now at least four more trams or run-ways were built. These were connected to the others, and ran north also. Lumber piles on the lake side were only about 15 feet from the edge that dropped into deep water. So some of these piles were placed where the water had been 10 feet deep.

Dam Built

Another project that was completed in the early days was installing a dam at the outlet of South Bar Lake.

This raised the water about 18 inches and helped to float the logs higher near the shore of the lake. It could also be raised or lowered. A chute made of lumber was now built from the dam to Lake Michigan, only a few rods north of the north dock so all the water coming out of the outlet went down the chute. And last, a strong narrow edging dock, about three feet above the water line, was built in six feet of water. This was on the north side, but close to the water from the outline from damming up. It also made a harbor for small boats.